Environmental Chambers

- Temperature Cycling

- Humidity Cycling

- Dust Test Chamber

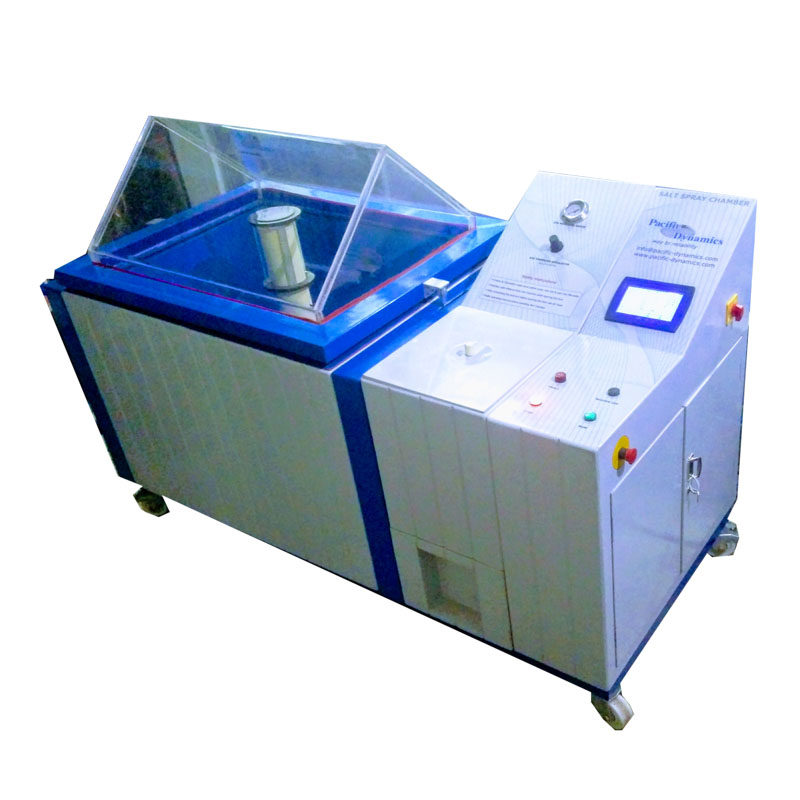

- Salt Spray Test Chamber

- Thermal Shock (2/3 One)

- Walk-in and Room size

- Ultra-Violet Test Chamber

- Rain Test Chamber

- Vibration Chamber

- Acoustic Chamber

- Heat (Hi-Temp) Chamber

- Cold Test Chamber

- Temperature & Humidity control

- Air/ Water cooling

- Energy efficient refrigeration

- Interior (SS)

- Exterior (SS or Powder coated)

- Adjustable Shelves

- Safety interlocks

- Fog-free viewing window

- PLC controller with touch screen

- PC interface/ Data logging

- Standalone or Vibration integrated type

- Compliance to various standards

Environmental/Climatic test chambers are designed and manufactured to simulate full range of temperature and humidity conditions so that the products can be tested for their performance and reliability inside the laboratory. We provide our customers standard and custom-designed environmental test chambers to meet their most demanding environmental testing solutions with ease-of-use, reliability and performance and include many user-friendly features yielding the best value in the industrial applications.

These test chambers can be used to test and validate the products for qualification and aging affect in a variety of climatic conditions which includes basic cycling to accelerated stress testing. Smart instrumentation and industry standard electrical paneling ensures safety to the chamber and the product under test with audio/ visual alarms and automatically stopping the operation. Port holes are made as per customer application for ease of cable routing and hassle free monitoring of output of DUT.

Refrigeration circuit have been designed to protect compressors in all operating conditions and also prolonging it’s life by keeping it cool. Refrigerants used are Non-CFC which are environmentally safe, non-flammable and non-explosive. Robust air circulator motors provide better airflow which improves controllability and temperature gradients . Fully welded ports and seams provide a hermetically sealed enclosure to prevent moisture ingress. The chamber exterior is constructed of formed sheet steel for structural strength and finished with a durable powder coat finish or customer specified paint combinations.

11

About Us

We are a trusted source for environmental testing solutions in present economical scenario.

Contact

- Khasra No. 986M & 987, Salampur, Rajputan Indistial Area, Roorkee, Uttarakhand - 247667

- +91-9012345127, +91-9837391375

- +91-1332-268848

- info@pacific-dynamics.com

- -- Website Here --