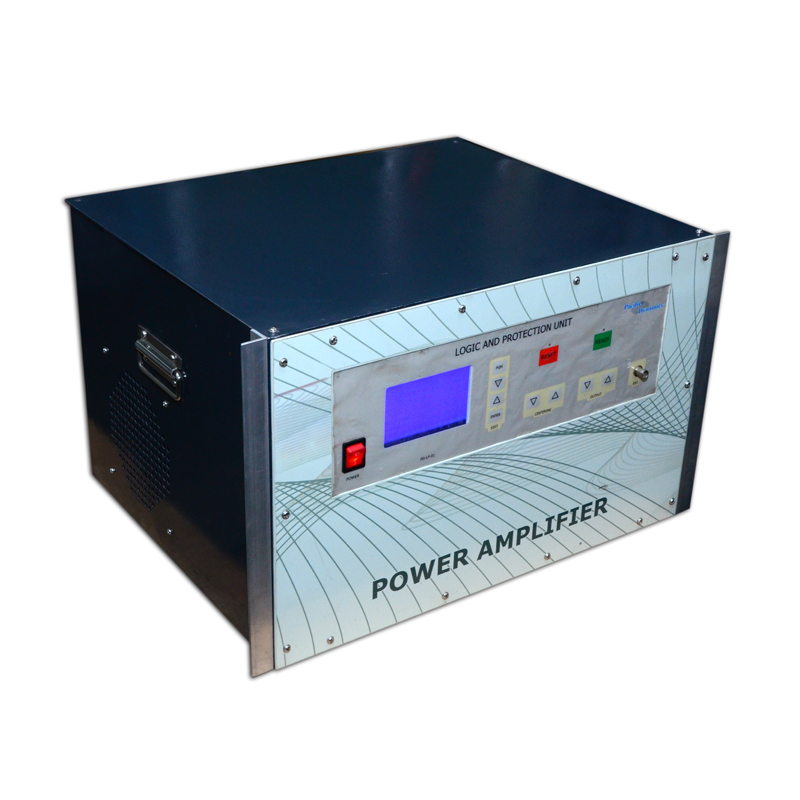

Digital Power Amplifiers/Replacement Amplifiers

The Power Amplifiers (or digital switching Power Amplifiers) provide very high level of efficiency with superior performance. The design of the PDA Series Power Amplifier ensures higher energy in less space. These Power Amplifiers use solid-state power devices such as MOSFETs or IGBT as their primary switching devices in a Class-D Full Bridge configuration. They are modulated digitally with a high frequency pulse-width-modulated signal. The modular construction is easy to handle and integral air cooled design ensures continuous duty cycle without sacrificing performance at peak temperature and humidity. These amplifiers are suitable for driving shakers from all manufacturers and designed to give uninterrupted rated voltage and current even at higher ambient temperature and humidity. The modular construction makes it easy to handle them and set up for utmost output power with direct coupling to any resistive or inductive load.

The low knee filter is used to provide smooth output for removing switching noise and electromagnetic interference. For impedance matching over a wide range of frequencies for inductive loads, a zobel network is dedicated. Variable current limit is provided for controlling maximum output power which also helps to avoid the accidents.

Major Sub Systems of the Power Amplifier-

a) Microcontroller based Digital Logic and Protection Unit (LPU)

The microcontroller based Digital Logic and Protection Unit (LPU) is used for control and monitoring the features and safety protections/interlocks of the PDA series Power Amplifier. The LPU is a user friendly interface between the user and the equipment and can be operated both in manual and auto modes. Machine parameters and trip interlocks are displayed on the alphanumeric display of the feather touch membrane keyboard provided at front panel. Soft start and controlled shut down is provided with an online key on the front panel with a emergency stop button.

Main Sub Systems of the Digital Logic Unit-

- Internal Oscillator

- Signal Source Selection

- Gain Control

- Auto Centering

b) Power Amplifier Remote

The Remote Operation Facility is provided as a separate module for applications that require remote control of the Power Amplifier and monitoring of all parameters and protection/interlocks on a PC. This feature provides complete functionality of the LCD screen and the feather touch membrane keyboard of Power Amplifier on the PC.

c) Power Module

The PDA series class D Power Amplifiers use high power density and efficiency of the Power Modules which are the main sub system. The power modules use MOSFETs or IGBTs as the primary switching devices and can be coupled with numerous types of loads varying from resistive to inductive. Each power module is rack mounted and copper bus bars are used in place of wires thus making it “wire-free” design to ensure that it never faces any issues like loose or damaged connections. Each power module comprises a built-in PWM generation and management. The formation of these modules is stacked in “Master-Slave Configuration” used for their parallel operation in the power amplifier. “Three-sigma design” ensures peak current capability for continuous random operation without affecting the life of the power device. Pulse Width Modulation in the paralleled modules is synchronised through “Master clock” and a current feedback network is applied for precise current sharing amongst modules.

Main Sub Systems of the Power Module-

- Driver Section

- Power Section

- Feedback Section

- Filter Section

d) HVDC Section

The Power Amplifiers do not require any special operating environment or support equipment and run on a widely acceptable range of 3-phase mains input. Three phase bridge rectifiers are used to rectify step down 3-phase output of extremely efficient impregnated transformer. Bridge rectifiers used are of single body construction for saving the space and good heat sinking characteristics, together with high voltage capacitors for suppressing transients and minimising mains ripples. Single Phase Preventer is used at the 3-phase input. It senses any phase loss and any imbalance in 3-phase line voltage making use of phase synchronisation relay. The Logic and Protection Unit also displays the phase status.

About Us

We are a trusted source for environmental testing solutions in present economical scenario.

Contact

- Khasra No. 986M & 987, Salampur, Rajputan Indistial Area, Roorkee, Uttarakhand - 247667

- +91-9012345127, +91-9837391375

- +91-1332-268848

- info@pacific-dynamics.com

- -- Website Here --